Whether you are building your first facility or expanding, the decision of whether to include climate-controlled units in the project is a common question. Higher rent, better land coverage, and the elimination of moisture and dust in the storage units serve as incentives to build. However, climate-controlled storage presents some unique considerations.

Does My Market Need It?

Climate-controlled storage usually generates higher income per square foot, but not always. In markets where larger operators have saturated the market with retail conversions or large multi-storage projects, standard drive-up storage may command a premium due to its convenience and a shortage of supply. Your market research should help you determine rates for climate-controlled versus standard storage. When comparing sites in your market, be aware that consumers prefer ground-level storage options when offered the choice between that or upper-level storage accessible via elevators.

Is It Climate-Controlled or Temp-Controlled?

Let’s start by discussing what climate-controlled storage means. Most operators will set the heat between 50 to 60 degrees, and the air conditioning around 80 degrees. Perhaps more importantly, climate-controlled storage should include dehumidification to limit humidity to 50%. During much of the year, you need neither heat nor air conditioning to keep a slab on grade building between 50 to 80 degrees, but you should control humidity to prevent mold and mildew. Without dehumidifiers, you have temperature-controlled storage, not climate controlled, and in humid climates you may still have conditions for mold and mildew.

What Type of Heating and Cooling Equipment is Needed?

The type of equipment used will vary by region and will generally be comparable to equipment in new home construction. In extreme northern climates, you may find some facilities that use a heated slab and have no air conditioning or air handling equipment at all. In most of the northern US, HVAC systems can generally cover up to 5000 square feet per zone with gas-fireed furnaces and conventional AC. Each conventional air handler requires a 5×10 mechanical room. In climates where heating needs are less extreme, smaller ceiling mounted AC/heat pump units, or mini-splits are more commonly used. These units tend to cover smaller zones, often around 2500 square feet each.

Your air conditioning unit will create condensation, so you’ll need to plan for a drain system in your building or drain to the exterior. High-efficiency (condensing) furnaces also create liquid condensation – which in winter months you cannot drain outside as it will freeze. Lower efficiency gas furnaces require a metal chimney through the roof. Higher efficiency “condensing” furnaces can be vented sideways through walls which is preferred to reduce leak risk.

The exterior portion of your air conditioner is the condenser. This should be located where your customers won’t run into it, or protected by bollards. The rear of the building, or in a recessed area is ideal. Avoid roof placement to minimize leaks.

How Much Insulation Do I Need?

Your energy code may dictate how much insulation you’ll need, but in some states, you can decide how much you wish to invest in efficiency. Consider this: better insulation pays you two ways – a more efficient building will lower your monthly utility expenses. The second way is that lower expenses mean higher NOI, which ultimately increases facility value when it’s time to sell or refinance.

I built my own facility in Wisconsin before current energy codes were implemented – selected 10” of fiberglass roof insulation and 6” of wall insulation. This level of insulation is economical to install and quite effective. In past decades it was more common to see just 6” of roof insulation but increasing energy costs have made it more attractive to use more. Your building manufacturer should also provide thermal blocks between the building structure and roof panels.

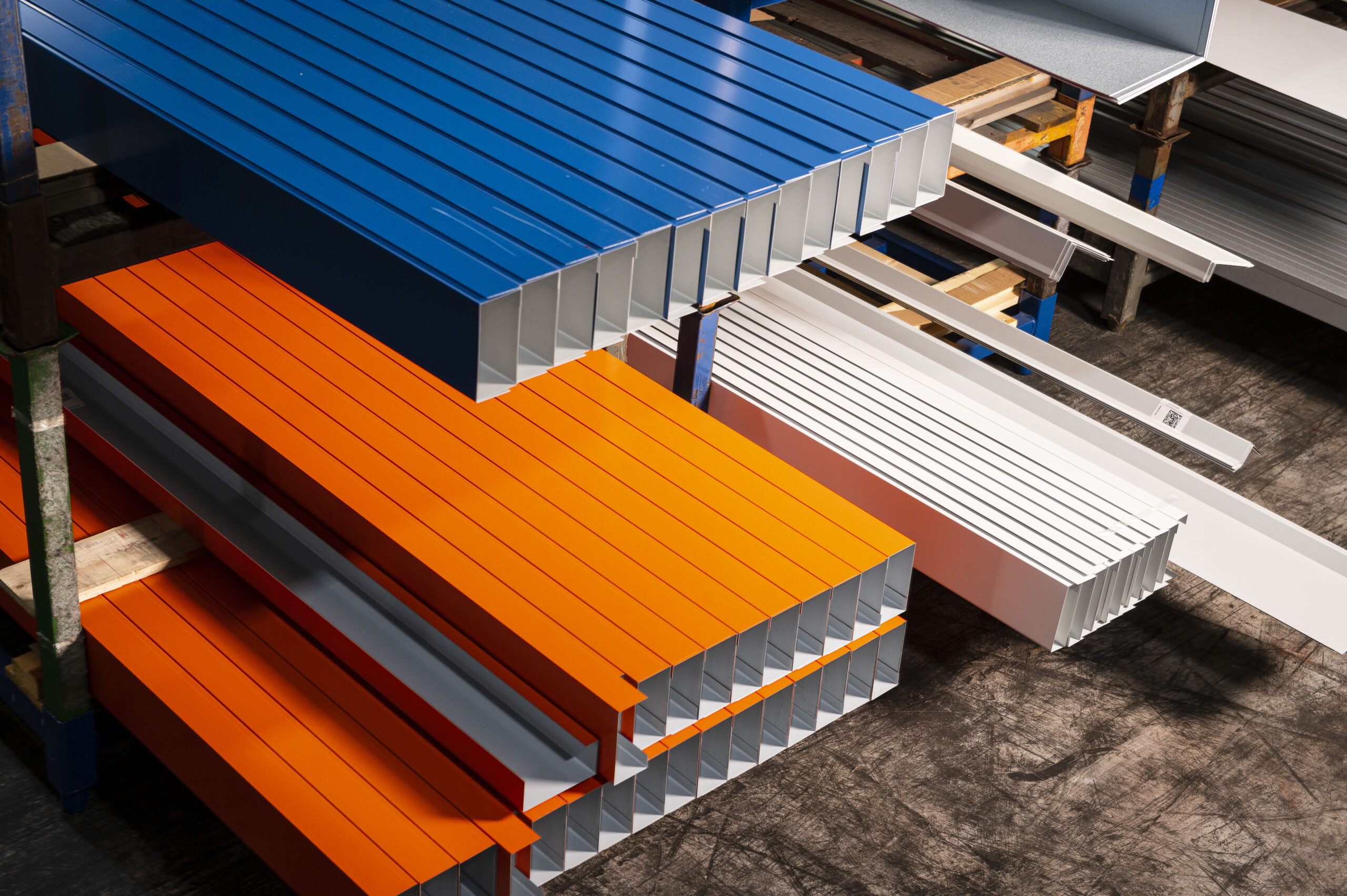

In areas with 2015 and newer energy codes, your building may require a more involved roof insulation system to better fill space between the purlins and avoid compressing the insulation. This can include additional strapping to support the insulation. Newer energy codes may also require uninterrupted wall insulation – this means that insulation between wall columns is not enough. Foam board with taped joints between the structure and exterior paneling is added to comply with the regulations. Or, insulated metal clad foam panels can address energy code and add a premium exterior finish at the same time.

How is The Layout Different with Climate-Controlled Storage?

Climate-controlled layouts will introduce some new design parameters. While standard drive-up storage is commonly 30 or 40 feet wide, climate-controlled buildings will have interior halls that lay out more efficiently in a 50 to 70-foot-wide building. Halls are usually 5’ wide, and units usually range from 5×5 to 10×20. Climate-controlled buildings can be built along lot lines with access to one side only. This reduces driveway expense and increases land utilization. Buildings can be even wider, but consult with your building manufacturer early in your planning process to understand any length limitations in roof panels and pitch. For very large buildings, rubber membrane (also known as TPO) roofs offer more design flexibility and interior drains.

Building layouts that don’t require customers to travel over 100’ to their unit are preferred. If your facility does have a variety of distances, consider implementing “Good/better/best” pricing. What this means is that you charge more for the most desirable units. Units that are less convenient offer you a low entry point and can be helpful in promotions. Providing platform carts at hallway entrances makes for an easier move-in for your clients.

Loading Areas

At its most basic level, interior climate-controlled storage units are accessed through a traditional swing door. These doors are usually recessed into the building to provide some shelter from weather and prevent the door from swinging into traffic in a driveway. Some developers opt for power sliding doors to improve on this design. For a better customer experience, a shade canopy, enclosed loading bays, or entire drive-through corridors can be included in the project.

Fire code is an additional design consideration. Depending on which year code your area observes, you may be allowed to have up to 12,000 square feet of area before you need a firewall or sprinklers. However, some areas allow only up to 2500, and the requirement can differ for interior vs exterior access units.

Exterior Climate Controlled Units

Exterior access storage is the best of both worlds. These climate-controlled units use insulated sectional doors to provide an airtight insulated door, for the ultimate in customer convenience. These units are relatively rare in the marketplace and can set your facility apart from others. They are popular in northern climates for classic car storage or as a more upscale option for typical moving needs.

The design and permitting process for climate-controlled storage can be more involved than traditional drive-up. You may need an additional design engineer (or your HVAC vendor may fill this role) to design your HVAC system. Using a separate HVAC design engineer adds some additional planning expense but does result in a situation where you will have an easier time sharing that plan with multiple contractors to provide bids. You may also need to provide life safety plans – this is planning to show that you have proper egress paths, emergency lighting, and ADA compliance.

If you are planning a new site or expansion, hopefully, we have provided you with ideas. Climate Controlled storage is a popular category with many benefits to customers and storage owners.